Spinning: Spinning is three types.

These are:

1. Melt spinning.

2. Dry spinning.

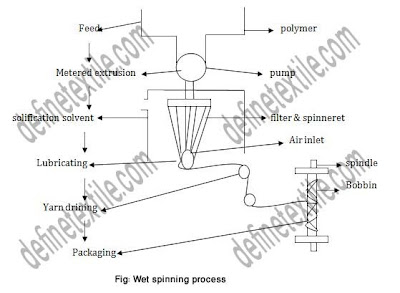

3. Wet spinning.

Melt Spinning: The process of

spinning by which fiber or filament is produced from melted polymer chips by

extruding though spinning continuous filament produced here.

Requirements:

1. The polymer should not be volatile.

2. The melting point of polymer should

be 30ºC less than its decomposition temperature.

Advantage:

1. Can be used for both staple and

continuous filament.

2. Direct and simple process.

3. No environment pollution.

4. High production speed (2500-3000)

ft/min.

5. Low investment cost.

Disadvantage:

1. Required more proper maintained of

machine.

2. Heat of input is high.

Dry

spinning: In dry spinning the fiber forming polymer dissolved in a volatile

solvent is introduced into a heated chamber where the solvent is evaporated and

solid fiber is obtained through spinneret.

Dry spinning

solvent:

Fiber

|

Solvent

|

Cellulose

|

acetone+(2-6)%water

|

Triacetate

|

Methylene

chloride40%+methyl formide10%

|

Poly

|

di-methyl

formamide or di-methyl acctamide

|

Spandex

|

DMF, DMAC

|

Modacryloic

|

Acetone

|

Properties

of solvent:

1. It should be volatile

2. It should be organic

3. It should have low boiling temp

4. It should have comparatively cheap

5. It should be non-toxic

Advantage:

1. suitable for staple fiber

2. Low temp required

3. Both organic & inorganic solvent

can be used

Disadvantage:

1. Slow production (150-200ft/min) speed

2. washing of fiber are needed

3. Toxic

Spinning reels come in very different price ranges . There are already spinning reels that could not only convince hobby anglers in the test. Weight and translation are just as important for a comparison of spinning reels as the braking system and the ball and roller bearings. The spinning reels are used to fish for pikeperch and perch, pike and trout. Depending on the model, the spinning reels in the test were suitable for Frisian, catfish and the sea. Price and quality are closely related for spinning reels, as the comparison shows. Because especially the higher priced models are in terms of longevity, Materials and smoothness just great.

ReplyDeleteBecause of the wide variety of products out there, shoppers are often in search of the best spinning reels.

Spinning reels are used for spin fishing. In the test, the castors have to be resilient and robust, because they sometimes fall on the floor. The material must also be of high quality and well made, because spinning reels are already ejected hundreds of times during a tour. Strong forces act on the brakes so that there is no need to cut back on quality. Spin fishing is all about pulling predatory fish ashore. These fish are very aggressive and often release their powers explosively. Therefore, the finely adjustable brake is especially important for spinning reels. If, on the other hand, the keyword line laying falls, it means that the line retraction and the ability to throw far and accurately. And for all of this to be fun even after half an hour, spinning reels have to be light. Otherwise lame arms and a sore muscle will quickly threaten. best spinning reels